Introduction to Foam Protective Packaging

In today’s world, ensuring the safe transportation and storage of valuable goods is paramount. Foam protective packaging plays a crucial role in safeguarding products during shipping, handling, and storage. This innovative packaging solution provides reliable protection against impacts, shocks, and environmental factors, making it ideal for various industries. From electronics to automotive, foam protective packaging is widely used to ensure that delicate items reach their destination intact.

One of the most versatile materials used in this type of packaging is polyethylene foam. This material offers numerous benefits, such as superior shock absorption, moisture resistance, and adaptability to different applications. Whether transporting fragile electronics, healthcare devices, or industrial tools, foam protective packaging ensures that the contents are safe from damage.

In this article, we will explore the different aspects of foam protective packaging, including its benefits, applications, and how it stands out as a reliable solution for various industries.

What is Foam Protective Packaging?

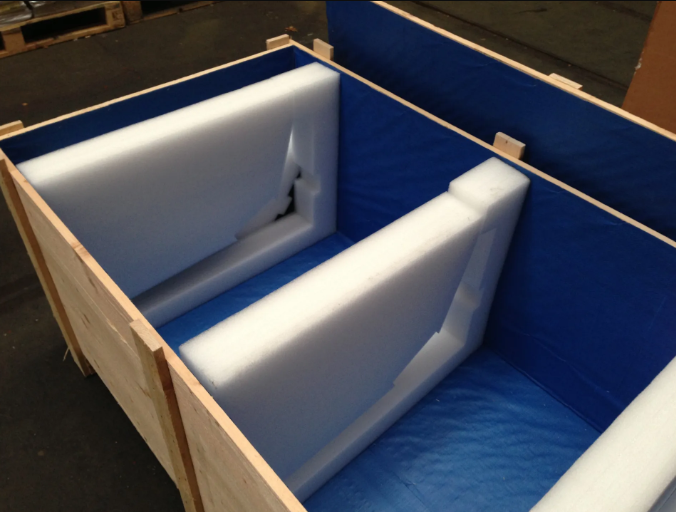

Foam protective packaging refers to the use of foam materials to provide cushioning and impact absorption for products during transit. Polyethylene foam, a popular choice in this category, is a cross-linked foam that offers excellent protection against repeated shocks. It is especially suitable for multi-trip packaging, factory transit applications, and more expensive items that require multiple layers of protection.

One of the key advantages of polyethylene foam is its ability to withstand multiple impacts without degrading. This makes it a perfect choice for goods that may experience rough handling or multiple drops during shipping. Available in a range of colors, including black, white, blue, and anti-static pink, foam protective packaging can be tailored to the specific needs of a product.

Moreover, polyethylene foam is often known by trade names like Ethafoam, Stratocell, and Jiffycell Polylam. Specialized foams such as Nomafoam, Plastazote, and Zotefoam are also used in custom applications, offering even greater flexibility.

Benefits of Foam Protective Packaging

1. Superior Shock Absorption

One of the primary reasons businesses opt for foam protective packaging is its ability to absorb and distribute impact forces. The foam’s structure consists of thousands of tiny air-filled cells that act as shock absorbers, reducing the risk of damage during transportation. This is particularly important for fragile or delicate items, such as electronics or glass products, that require added care during handling.

2. Multi-Trip Durability

Polyethylene foam stands out for its durability, especially in multi-trip or reusable packaging solutions. Unlike some materials that lose their protective properties after one impact, foam protective packaging maintains its integrity through multiple uses. This makes it ideal for industries where goods are transported repeatedly, such as in factory settings or for high-value products.

3. Moisture and Chemical Resistance

Another advantage of foam protective packaging is its resistance to moisture, chemicals, and temperature fluctuations. Products such as electronic devices, which are sensitive to these factors, benefit from the added layer of protection provided by foam. The foam barrier prevents moisture ingress, ensuring that items remain safe from rust, corrosion, or other forms of damage caused by environmental exposure.

4. Versatility in Design

Foam protective packaging is highly adaptable and can be customized to fit the exact shape and size of a product. This level of versatility ensures that each item receives the best possible protection, regardless of its shape or fragility. Custom molds and inserts can be created to cradle delicate parts, providing maximum protection with minimal material waste.

5. Lightweight Material

While foam offers exceptional protection, it is also lightweight. This is particularly beneficial for reducing shipping costs, as the added weight of packaging is minimized. Businesses can protect their goods without incurring significant additional expenses due to the packaging material itself.

Applications of Foam Protective Packaging

1. Electronics Industry

The electronics industry heavily relies on foam protective packaging to ensure that sensitive devices such as smartphones, tablets, and computer components reach consumers in perfect condition. Polyethylene foam provides both shock absorption and protection against static electricity, making it an ideal choice for these applications.

2. Automotive Industry

In the automotive sector, foam protective packaging is used to safeguard vehicle components during assembly and transportation. Whether it’s delicate engine parts or fragile glass components, foam ensures that these items are shielded from the bumps and vibrations experienced during transit.

3. Healthcare Sector

The healthcare industry uses foam protective packaging for transporting medical devices, surgical instruments, and diagnostic equipment. In these applications, it is vital to prevent any damage that could compromise the functionality of the products. Foam offers a reliable solution for ensuring that these high-value items arrive safely.

4. Tool and Equipment Packaging

For tools and equipment, especially those used in industrial settings, foam protective packaging offers tailored protection. The foam can be molded to fit specific tool shapes, ensuring that each item is securely housed and protected from impact. Polystyrene packaging, which is also a form of foam, is often used for toolboxes to keep tools organized and safe during transit.

Customization of Foam Protective Packaging

One of the key strengths of foam protective packaging is its customizability. Foam can be die-cut, molded, or cut into specific shapes to accommodate products of all sizes and shapes. This ensures that each item is securely protected and efficiently packed.

Custom foam inserts are commonly used for toolboxes, where each tool has its dedicated slot. This not only provides protection but also enhances organization, ensuring that items are easy to locate and retrieve. Foam’s ability to be shaped and cut to precise dimensions makes it an invaluable material for custom packaging solutions.

Complete Packaging Solutions

In addition to providing foam protective packaging, many companies offer complete packaging solutions that include boxes, cartons, and other materials such as bubble wrap or tape. This simplifies the packaging process by ensuring that the foam inserts are matched to the carton strength, providing the best value for money.

When businesses order their packaging from a single supplier, they benefit from streamlined processes, faster response times, and consistent quality. Packaging companies can often source any additional materials required for complete packaging solutions, ensuring that the customer receives a package that meets their exact needs.

Conclusion

In summary, foam protective packaging is an essential solution for businesses that require reliable, cost-effective protection for their products. Its versatility, durability, and superior shock absorption properties make it the material of choice for industries ranging from electronics to healthcare. By providing a barrier against moisture, chemicals, and temperature fluctuations, foam protective packaging ensures that goods arrive at their destination in perfect condition.

For businesses that need reusable, custom-designed packaging solutions, polyethylene foam is an excellent option. It delivers unmatched protection for multi-trip applications, ensuring that high-value goods are safeguarded throughout their journey. With the ability to tailor packaging to specific needs, foam protective packaging remains an innovative and indispensable part of modern logistics.