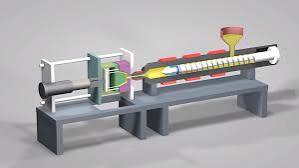

Injection molding is a manufacturing process renowned for its efficiency and precision. It’s commonly associated with everyday items like plastic bottles and toy components. However, this versatile technique extends far beyond these basic applications. Let’s delve into some of the more surprising and innovative products crafted through injection molding, showcasing the breadth of this technology.

1. Medical Devices

Injection molding is a cornerstone in the production of medical devices. While it might not be immediately obvious, many medical instruments and components are made using this technique. For instance, injection molding is used to create intricate parts for diagnostic devices, such as MRI and CT scanners.

The precision and consistency required in these parts make injection molding an ideal choice. Additionally, components for life-saving equipment like insulin pens and inhalers are manufactured using injection molding, where the accuracy and reliability of the parts are crucial for patient safety.

2. Automotive Components

The automotive industry relies heavily on injection molding for producing a variety of components. Beyond the obvious parts like dashboard panels and trim pieces, injection molding is used to manufacture high-performance parts such as air intake manifolds and engine covers.

The ability to produce complex geometries and ensure tight tolerances makes injection molding indispensable in this sector. Moreover, advancements in material science have led to the development of high-strength polymers that meet the rigorous demands of automotive applications.

3. Electronic Housings and Components

In the realm of electronics, injection molding plays a vital role in creating housings for everything from smartphones to consumer electronics. The sleek and ergonomic designs of modern gadgets often owe their existence to injection molding’s ability to create intricate, detailed enclosures.

Furthermore, injection molding is used to produce internal components such as connectors, housings, and circuit boards. The process allows for precise fitting and high-quality finishes, which are essential for the functionality and aesthetics of electronic devices.

4. Sports Equipment

Injection molding also finds its way into the world of sports and recreation. High-performance sports gear such as helmets, protective pads, and even bicycle components are often made using this technique. The ability to mold complex shapes and incorporate lightweight, durable materials is crucial in sports equipment, where safety and performance are paramount.

For example, the impact-resistant properties of injection-molded materials make them ideal for protective gear that can absorb and dissipate energy during high-impact activities.

5. Household Appliances

In the kitchen and home appliance sector, injection molding is used to create a variety of functional and aesthetically pleasing products. Items such as coffee makers, blenders, and even parts of dishwashers are produced using this technique.

The precision and consistency of injection molding ensure that these appliances are both efficient and durable. Additionally, the ability to produce custom colors and finishes allows for a wide range of designs that complement modern kitchen aesthetics.

6. Furniture Components

Surprisingly, injection molding is also employed in the furniture industry. Components such as chair bases, table legs, and even ergonomic support elements are made using this technique. The ability to mold complex shapes and integrate functional features makes injection molding a valuable tool in furniture design.

For instance, some modern office chairs utilize injection-molded parts for their adjustable mechanisms, offering both comfort and functionality.

7. Consumer Goods and Toys

Beyond the familiar toys and gadgets, injection molding is used to produce a diverse range of consumer goods. From customized phone cases to unique kitchen gadgets, the versatility of injection molding allows for creative and functional designs.

The process is also used to manufacture collectible items and novelty products, where detailed and intricate designs are essential for capturing consumer interest.

8. Aerospace Components

The aerospace industry benefits from injection molding through the production of lightweight and high-strength components. Parts such as ventilation grills, housing for avionics, and interior panels are manufactured using this technique.

The precision and reliability required in aerospace applications make injection molding an ideal choice, as it ensures that components meet stringent safety and performance standards.

Conclusion

Injection molding is not merely a technique for crafting simple plastic products; it is a sophisticated process capable of producing intricate shapes with remarkable precision. This versatility makes it essential across a broad range of industries, including medical devices, automotive components, consumer goods, and aerospace parts.

As technology evolves, the potential applications for injection molding will continue to grow, driving innovations and pushing the limits of what this adaptable manufacturing method can accomplish. Additionally, the integration of heating oil systems in the process can enhance efficiency and control, further expanding its capabilities and applications.